I have been lurking here for a while not doing much posting as I read and used the search button and sort of got to know the board.

I have only been into Home machining a couple of years but was always into metal and fab work. This must be the most addictive hobby I have ever had!

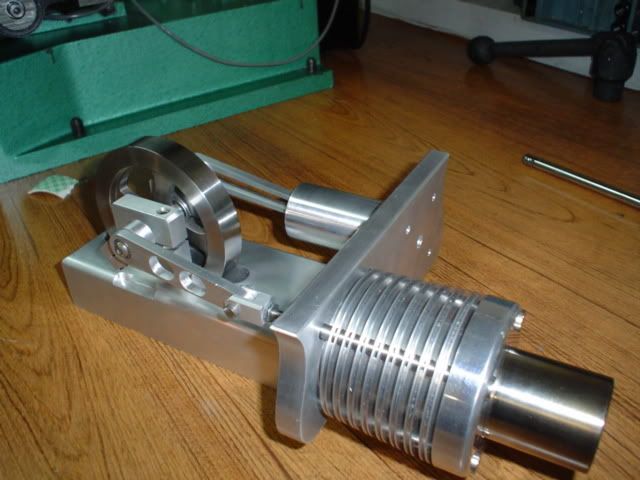

I decided to build the Stirling engine featured in HSM DEC/05 after building the Crusader .60 which ran like crap(not enough compression),

I am using the plans as a guideline and just sort of having fun giving it a different look.

The flywheel is stainless and so is the hot cap. I must say turning the stainless hot cap and flywheel in my little 9x20 import lathe was a challenge but I think they turned out pretty well.I grooved the hot cap flange surface to restrict the heat path area a bit. No idea if it will help but will help the gasket to seal at least.Or if nothing else I got to make some little grooves for fun.

I'll probably tackle the cold end this weekend.

Steve

I have only been into Home machining a couple of years but was always into metal and fab work. This must be the most addictive hobby I have ever had!

I decided to build the Stirling engine featured in HSM DEC/05 after building the Crusader .60 which ran like crap(not enough compression),

I am using the plans as a guideline and just sort of having fun giving it a different look.

The flywheel is stainless and so is the hot cap. I must say turning the stainless hot cap and flywheel in my little 9x20 import lathe was a challenge but I think they turned out pretty well.I grooved the hot cap flange surface to restrict the heat path area a bit. No idea if it will help but will help the gasket to seal at least.Or if nothing else I got to make some little grooves for fun.

I'll probably tackle the cold end this weekend.

Steve

.png)

Comment