I stumbled onto the concept for this little bandsaw aid a few weeks ago. It may be an old trick but I haven't run across it yet.

I was cutting a big (for me) chunk of 1/2" plate on my little 4x6 H/F bandsaw. Part of it wouldn't fit past the frame so I chain-drilled & broke off a chunk. Later that day I needed to shorten a 1" socket head screw to 5/8". I was cutting it off in the bandsaw but the head of the screw of course made the cut awkward & crooked. I was looking around for a piece of scrap to space the screw off the table a bit when I picked up a 1/4" thick piece of aluminum scrap with the sawed off chain-drilled holes down one side. The screw I was cutting was a 1/4" so it dropped snugly down into one of the half-holes. EUREKA, the light bulb switched on!

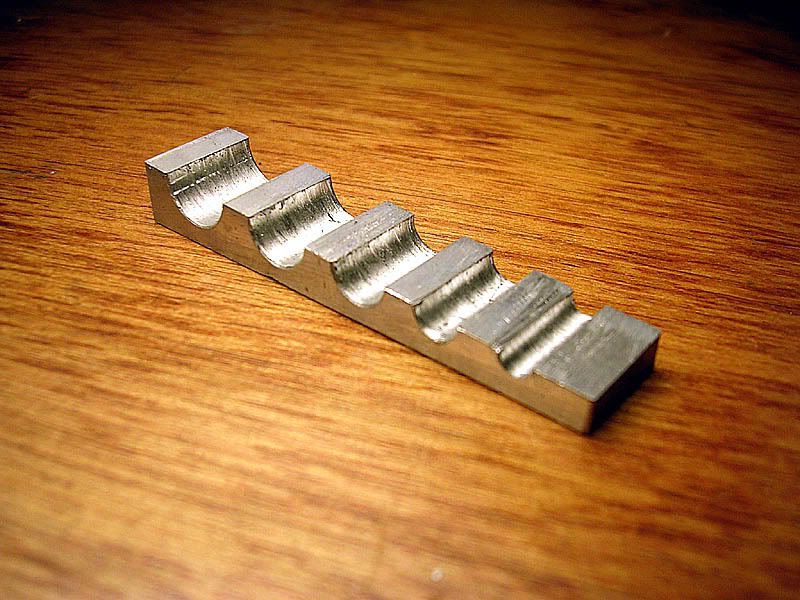

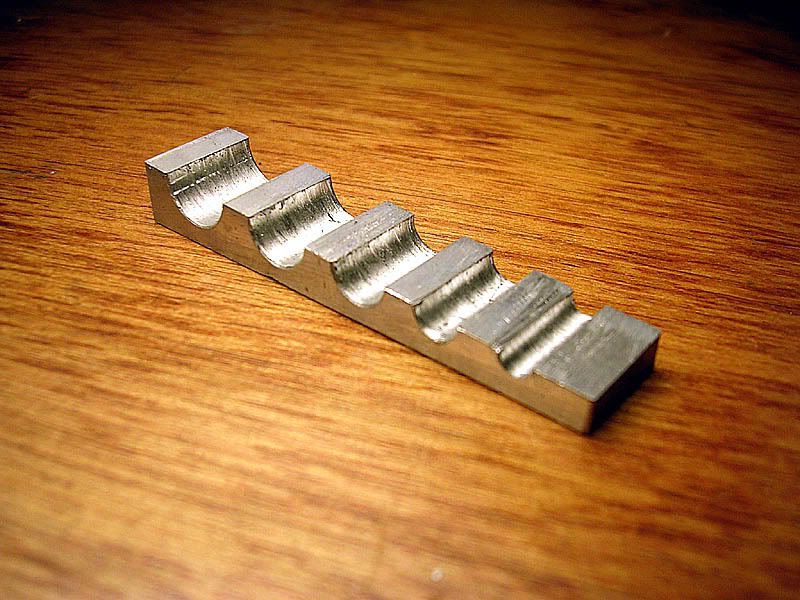

The pictures are self explanatory. I drew up a nicer version in CAD with the 3/8" thru #6 holes spaced so that the standard hex-head sizes would clear the table. I squared up & zeroed a piece of scrap and then drilled the holes using the coordinate method in the mill. Bolts are now easily held parallel to the saw table and are cradled snugly for a no-slip process.

I was cutting a big (for me) chunk of 1/2" plate on my little 4x6 H/F bandsaw. Part of it wouldn't fit past the frame so I chain-drilled & broke off a chunk. Later that day I needed to shorten a 1" socket head screw to 5/8". I was cutting it off in the bandsaw but the head of the screw of course made the cut awkward & crooked. I was looking around for a piece of scrap to space the screw off the table a bit when I picked up a 1/4" thick piece of aluminum scrap with the sawed off chain-drilled holes down one side. The screw I was cutting was a 1/4" so it dropped snugly down into one of the half-holes. EUREKA, the light bulb switched on!

The pictures are self explanatory. I drew up a nicer version in CAD with the 3/8" thru #6 holes spaced so that the standard hex-head sizes would clear the table. I squared up & zeroed a piece of scrap and then drilled the holes using the coordinate method in the mill. Bolts are now easily held parallel to the saw table and are cradled snugly for a no-slip process.

.png)

Comment