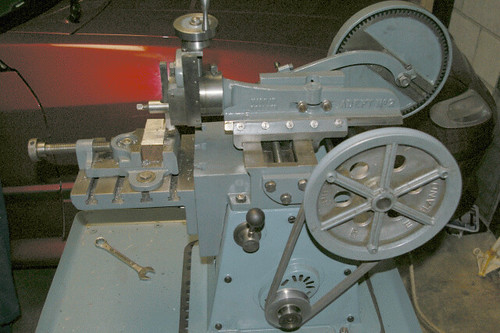

I don't have room of a shaper, but one of you on the west coast might have a need and a spot for a Atlas Shaper. There is a Atlas 7B shaper on Craig's List for sale.

I have no connection with it, I just thought someone might like to look.

Mel

I have no connection with it, I just thought someone might like to look.

Mel

.png)

Comment