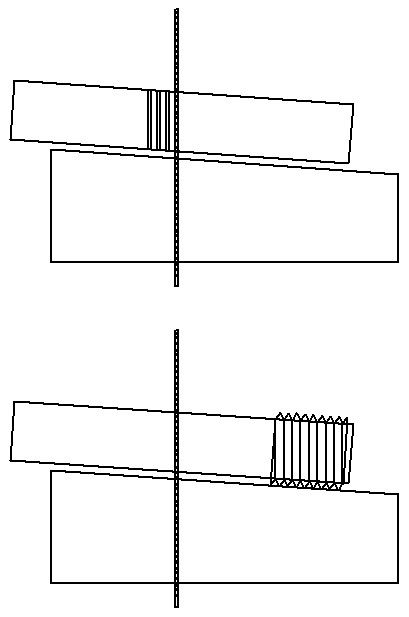

My little MicroMill is missing the X-axis stepper motor coupling. I contacted the nice lady at Sherline but their couplers are different than what came on mine. Anybody know where to source one of these at a reasonably price?

The ones I saw on the bay aren't the same but look easy to make. Anybody ever made one?

The ones I saw on the bay aren't the same but look easy to make. Anybody ever made one?

.png)

Comment