I posted a similar thread at PM,

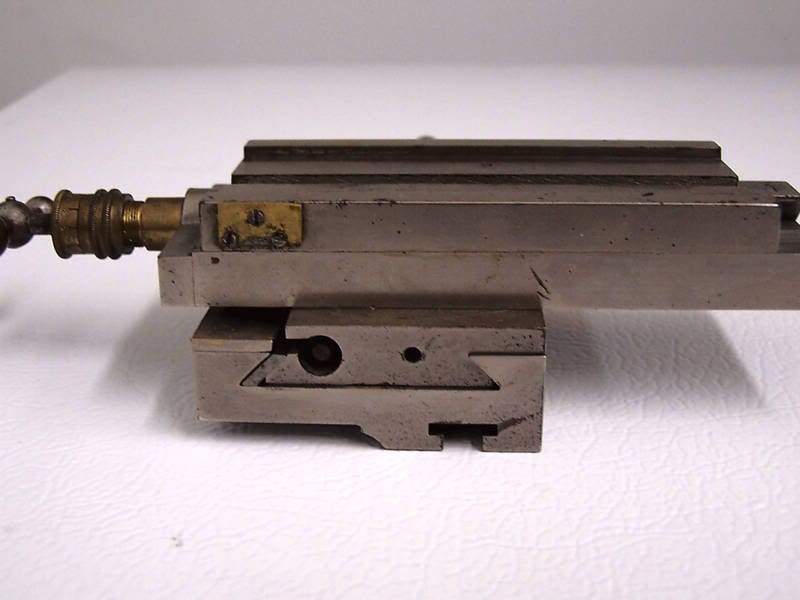

I have a old Stark no3, The slide rest is not made by Stark it seems.

But I do not understand why it was designed with a exposed leadscrew, and no flat surface for the dovetail other than on the degree radius on this side?

At first I thought this slide had the dovetail flat broken off on the leadscrew side.

But after more research I found several other topslides made like this.

This is what I have-

The topslide with a exposed leadscrew and no flat part of the dovetail -

And here is a Hardinge/Cataract topslide pic taken from http://www.lathes.co.uk/ showing the exact same design.

And I found several other topslides with this design used on the old precision bench lathes.

I don't get it and see no benefit, why did several lathe builders use this design?

Steve

I have a old Stark no3, The slide rest is not made by Stark it seems.

But I do not understand why it was designed with a exposed leadscrew, and no flat surface for the dovetail other than on the degree radius on this side?

At first I thought this slide had the dovetail flat broken off on the leadscrew side.

But after more research I found several other topslides made like this.

This is what I have-

The topslide with a exposed leadscrew and no flat part of the dovetail -

And here is a Hardinge/Cataract topslide pic taken from http://www.lathes.co.uk/ showing the exact same design.

And I found several other topslides with this design used on the old precision bench lathes.

I don't get it and see no benefit, why did several lathe builders use this design?

Steve

.png)

Comment