Hi,

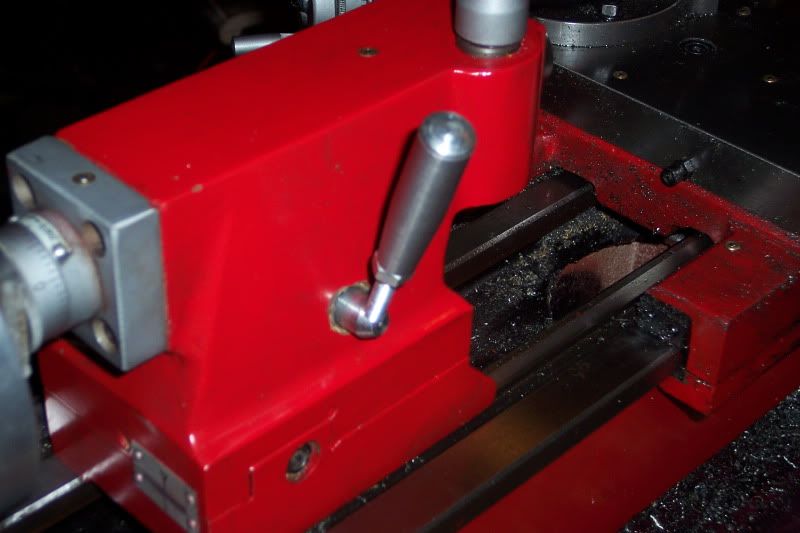

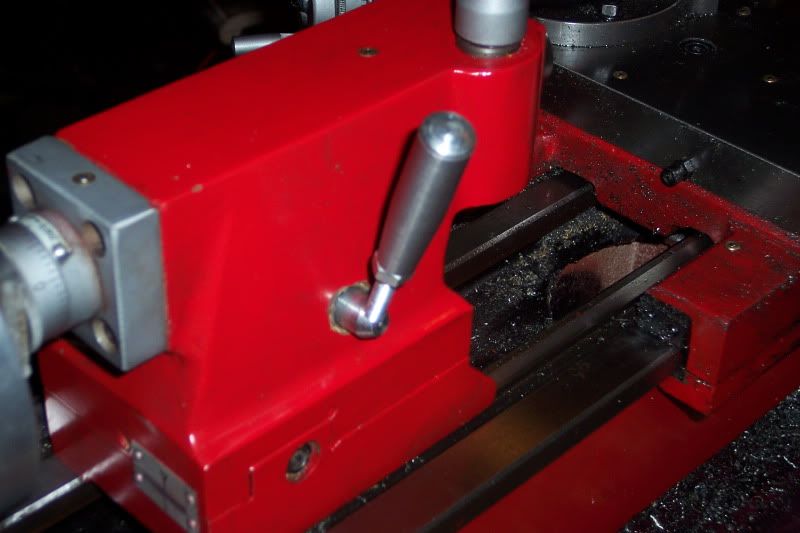

Since I had a little free time and the weather is warming a bit, to almost 40! I decided to do a little modification to my little lathe. I have never liked using a wrench to tighten and loosen the clamp bolt on a tail stock. So I rummaged up a couple of old rusty 1/2" bolts and made a cam lock for my tail stock.

After I had it assembled, I was standing there self-satisfyingly admiring my handiwork. And I was thinking that I'm not going to ever be irritated by the simple nut and bolt that was the original set up. When the thought occurred to me. It doesn't bother me to change step pulleys for speeds, I got time for that. And not even having a QC gear box is no big deal. It's not like I'm going to need to single point 20 different thread pitches in less than an hour. But it seems this old coot can't be bothered to give a small wrench a 1/2 turn to tighten or loosen a nut. It's odd what little things we seem to not be able to put up with sometimes isn't it.

dalee

Since I had a little free time and the weather is warming a bit, to almost 40! I decided to do a little modification to my little lathe. I have never liked using a wrench to tighten and loosen the clamp bolt on a tail stock. So I rummaged up a couple of old rusty 1/2" bolts and made a cam lock for my tail stock.

After I had it assembled, I was standing there self-satisfyingly admiring my handiwork. And I was thinking that I'm not going to ever be irritated by the simple nut and bolt that was the original set up. When the thought occurred to me. It doesn't bother me to change step pulleys for speeds, I got time for that. And not even having a QC gear box is no big deal. It's not like I'm going to need to single point 20 different thread pitches in less than an hour. But it seems this old coot can't be bothered to give a small wrench a 1/2 turn to tighten or loosen a nut. It's odd what little things we seem to not be able to put up with sometimes isn't it.

dalee

.png)

- camlocks are not generally as solid as a bolt. I know what you mean though, there's certain fluidness when you're really cooking....and that wrench turn just never fits the flow

- camlocks are not generally as solid as a bolt. I know what you mean though, there's certain fluidness when you're really cooking....and that wrench turn just never fits the flow

Maybe that's why I have a hard time selling any of my stuff.

Maybe that's why I have a hard time selling any of my stuff.

Now all I need to do is find time to do mine the same

Now all I need to do is find time to do mine the same

Comment