Ok, ok, I've been turning wrenches and screwdrivers for a number of years and it's about damn time I figured out what the hell the deal is with JIS screws/drivers. I tinker with a fair amount of Japanese made engines and carbs so I should be able to put what I have learned into practice soon (I'm working on a Daihatsu with a carb issue today). Here is what I have gathered so far:

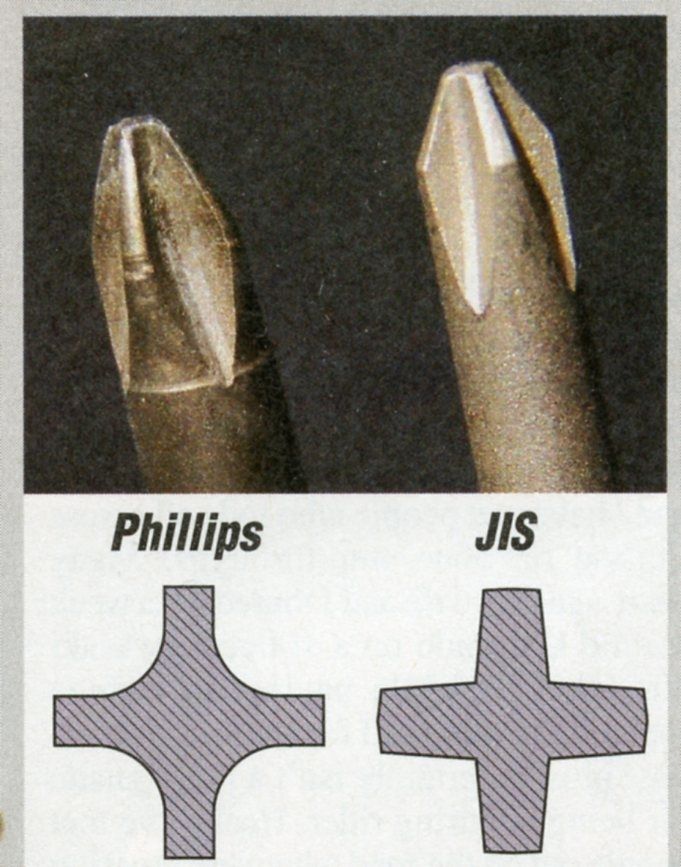

1) "The JIS B 1012 is commonly found in Japanese equipment. It looks like a Phillips screw, but is designed not to cam out and will therefore be damaged by a Phillips screwdriver if it is too tight." -Wikipedia

2) JIS bits are not available from McMaster-Carr or Lawson (my preferred vendors) but the entire screwdrivers are available from McMaster. I'm ordering the set of (3) 53325A61 for $38.37. Oddly, I can get a bit set with dozens of different typical and exotic shapes (pozidriv, torq-set, tamper-resistant hex, torx, Dooly's mountain dew driver, Tanya's twirl twister etc.) but no JIS bits.

3) JIS screws are available from McMaster but only in metric sizes. My Daihatsu is missing a screw on the carb and my dealer can't get it. I might order a small screw assortment.

4) Are JIS screws better since they are "designed not to cam out"?

5) Were phillips designed to cam out?

-Roland

1) "The JIS B 1012 is commonly found in Japanese equipment. It looks like a Phillips screw, but is designed not to cam out and will therefore be damaged by a Phillips screwdriver if it is too tight." -Wikipedia

2) JIS bits are not available from McMaster-Carr or Lawson (my preferred vendors) but the entire screwdrivers are available from McMaster. I'm ordering the set of (3) 53325A61 for $38.37. Oddly, I can get a bit set with dozens of different typical and exotic shapes (pozidriv, torq-set, tamper-resistant hex, torx, Dooly's mountain dew driver, Tanya's twirl twister etc.) but no JIS bits.

3) JIS screws are available from McMaster but only in metric sizes. My Daihatsu is missing a screw on the carb and my dealer can't get it. I might order a small screw assortment.

4) Are JIS screws better since they are "designed not to cam out"?

5) Were phillips designed to cam out?

-Roland

.png)

Comment