Quite simple really.

Find the part position in X and Y, move to the hole position.

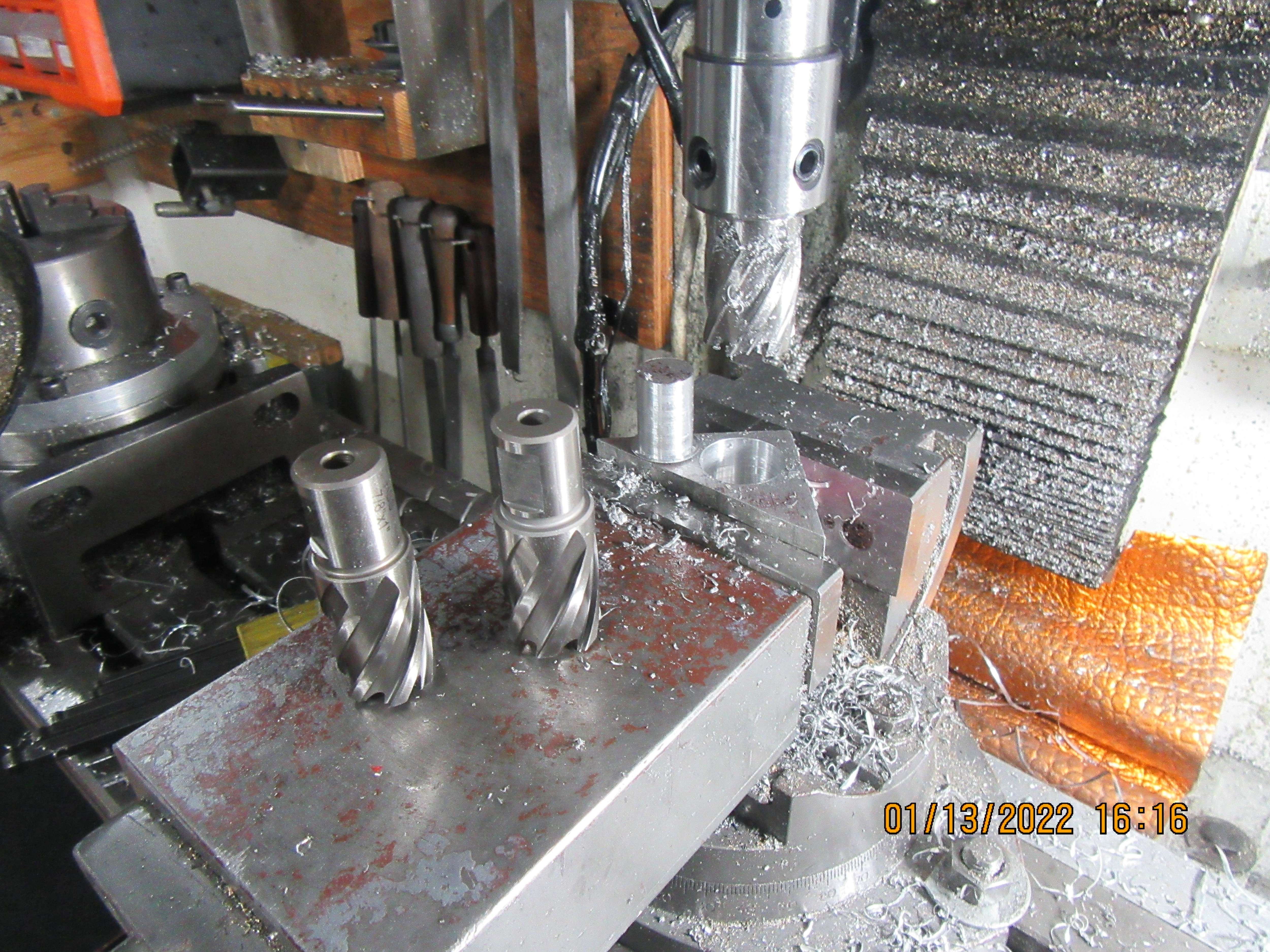

Place Annular cutter in the spindle and produce hole.

Find the part position in X and Y, move to the hole position.

Place Annular cutter in the spindle and produce hole.

.png)

Comment